Products

Duct Attenuator

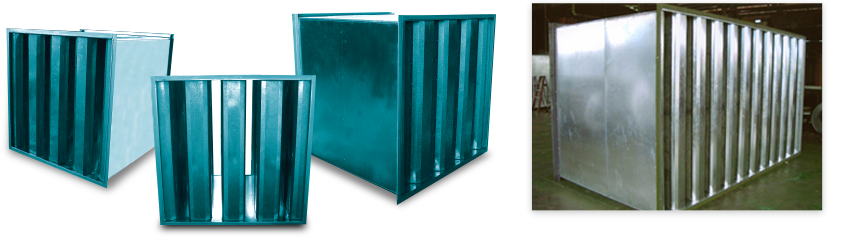

ALFA duct attenuators are specially made for use in situations where it is necessary to reduce the noise in “air moving” applications such as air conditioning or ventilation systems, fan and blower inlets and outlets, dust control equipment, motor cooling fans, enclosure ventilation, diesel generator sets, compressors, pump house and other industrial applications.

CONSTRUCTION

ALFA duct attenuators are constructed from heavy gauge galvanised sheet metal casing, containing a number of splitters filled with rockwool or fiberglass which divides the silencer into separate longitudinal airways. The standard construction of ALFA duct attenuator remain it integrity up to a maximum pressure of 2000 Pa and continuous temperature exposure up to 260 degree C. Sound is attenuated by the acoustic infill in the splitters when the air passes through these airways. The special aerodynamic design of the

splitters has the best sound attenuation and pressure drop.

For special applications, such as high face velocity system or oily environment, a special acoustically transparent lamina can be inserted in between the perforated galvanized steel sheet and acoustic infill. Depend to the application; the lamina material can be glass tissue facing or polyester film.

ACOUSTIC PERFOMANCE

The sound insertion loss performance of the ALFA duct silencer has been determined from measurement carried out in an independent Singapore laboratory — PSB Corporation. In Accordance with ISO 7235: 1991(E) “Acoustic – measurement procedures for ducted silencers – insertion loss, flow noise and total pressure loss”.

TYPES & MODEL

ALFA offer a range of standard duct attenuators come with combination of eight different lengths (600mm to 3000mm), two splitter size (200mm and 300mm width) and eight different airways (75mm to 300mm). Intermediate sizes are available for custom design silencer.

DETERMINE DUCT ATTENUATOR WEIGHT

For MF Series (Splitter Width 200mm)

Weight (kg) = 40 x Number of Module x Height (in meter) x Length (in meter)

For LF Series (Splitter Width 300mm)

Weight (kg) = 65 x Number of Module x Height (in meter) x Length (in meter)

* Module Width refer to table (Module width is the splitter width plus airway width)

* Number of Modules = Attenuator Width (in mm) / Module Width (in mm)

DETERMINE PRESSURE DROP

The pressure drop across the attenuators can be detemined as following steps:

- Step 1: Determine the attenuator model, width (in meter) and height (in meter)

- Step 2: Determine the air velocity (V) approaching attenuator – m/s

- Step 3: Detelmine the “K” Factor from the table

- Step 4: Pressure Drop Calculation in Pascal (Pa) = KV2

Where K : “K” factor (refer to “K” factor table)

V : Airflow (m3/s) / cross-sectional area of the silencer (Width x Height)